Back to the Article Section

ROVER-HAULIN

ROVER-HAULIN

THURSDAY 9:00AM

The crew of ECR heads out to our lot to rescue the "dry docked"

QE I and drive it into the shop, but it won't give up that easily. Although

it is a running 88, this cold winter morning it just won't start and it

won't budge.

One way or another the 88 is going into the shop, so with a tug from the

ECR D90, known on this site as "The Banana", the QE I breaks

free and is pulled into the shop, but it isn't going without a fight.

In one last defiant act the Series IIA lets us know just how bad off it

really is. As Steve hits the brakes to bring the Rover to a stop inside

the shop, the left rear brake pipe bursts and dumps the brake fluid out

of the system. Keep in mind that this 88 has single circuit brakes, so

this failure on the road would have meant that the 88 had no brakes.

At first glance this Series IIA 88 doesn't look that bad. Sure, it hit

a deer and has a mashed fender, but it looks good in the photo, right?

This photo is exactly the reason we keep preaching all over this web site

that you should never buy a Rover without looking it over first. All Rovers

look quite nice in this type of picture, but it is what lurks beneath that

matters. As we take this 88 apart and you see the images of what we find,

keep this image in mind, and then think about that next time you want to

bid on eBay for a Rover you've never seen, driven or had professionally

evaluated.

At this stage we have to go over the 88 from front to back and see what

we need to get ordered, what need we get form our inventory, what needs

work and what is ready to go to paint. The accident with the deer did some

minor damage to the fender, but it pushed the radiator support back and

wrecked the radiator, so it looks minor, but it did some nasty things.

The impact of the deer was the final straw for the rust weakened radiator

support. The bottom edge has basically let got and buckled all the way

across. The radiator support is a goner, as is the grill and the badly

rusted headlight buckets.

The frame is has been living on borrowed time for years. Some years ago

we replaced the rear crossmember, but that didn't cure the rust in the

rest of the frame. Patch upon patch upon patch can be seen in just the

right front frame horn, and you can even see a new rust hole coming through

all those patches. The frame is toast.

The hood of the Rover is also too far gone to save. The weight of the spare

tire combined with a broken hood latch for the past few years means that

the framework of the hood has broken and the skin has cracked.

The hood's framework is so rusted that pieces are starting to break off

and fall out of it. The cracks in the steel frame that support the alloy

hood skin are all the way through and the hood feels like it is going to

implode with the weight of the tire as you open it. A new hood will be

needed.

We already know that the brake system has failed, and that it is the early

troublesome and unsafe single circuit system, so that is all going bye-bye.

The clutch master has also seized from sitting and all the hydraulic fluid

pipes are rusted and about to blow just like the rear pipe did on the way

into the shop. Everything goes, these two system have to be right, you

can't half-ass your brakes.

The cooling system was in pretty good shape, but after the accident the

fan went through the radiator and the shroud broke in half. The hoses are

also showing their age, so other than the water pump, the cooling and heating

system will be replaced. Also needed are fuel filters, fuel lines a battery

hold down and much more.

Ah..well... we guess you could call this the bottom of the driver's door

frame, but there really isn't that much of it left. The door has basically

no structure left. The RH door is even worse. It is time for new doors.

The interior of the Rover is sporting the hottest new trend that is all

the rage in Hollywood. Its called the "sticky duct tape" look

and all the hottest people really want this look. It is especially fun

on hot days when the goo from the duct tape sticks to your clothes. Seriously,

all the cushions have seen better days and the end brackets on the LH and

RH seats are broken so the seats just flop around.

The interior of the bulkhead is just as nasty as the seats. There is no

paint left on most of the surfaces and almost nothing works. The steering

wheel isn't the right one for the year of the Rover and there are numerous

other parts that aren't correct for the model.

The rest of the bulkhead and interior don't look any better. The defroster

tubes are broken in half and when we turned the key to test it the ignition

switch fell apart inside.

Underneath the 88 things don't get any better. The springs are badly rusted

and sagging even though they have been soaked with a liberal coating of

oil from the mechanical parts above that leak all over the place. One of

the spring plates down here is even cracked in half. Luckily the Rover

will be getting a new parabolic suspension so none of this will slow us

down.

This image is of the RH footwell area and the Kodiak heater. The good news

is that the heater will be easy to remove as it just fell out of the Rover.

The bad news is that the bulkhead on this 88 is looking really bad. It

will be touch and go if we can even save it, and we have saved some pretty

bad bulkheads over the years. So that is it for a general quick walk around

the Series IIA 88. It isn't a pretty picture and 6 days is looking pretty

tight with everything we have found so far. The scary thing is that we

haven't even started to pull the 88 apart yet, and usually all the really

scary things that need work are found once you start to tear the Rover

apart.

R.I.P.

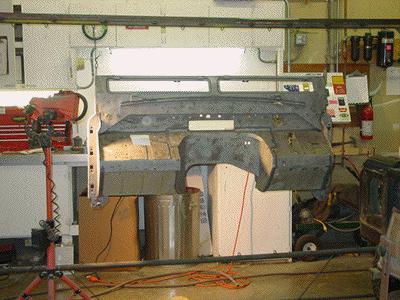

To some that stands for Rest In Peace, and to most that is where this 88

would have ended up. To the crew at ECR, R.I.P. stands for Rip It to Pieces,

or the first step in any real build up of a Rover, tearing it down to get

to what needs to be fixed, and in this 88 that means all the way down to

the frame. You can see we have already removed the easy to get at parts

like the doors, soft top, hood, etc. As each piece is removed any small

parts from it are saved as required, and the rest heads to the scrap pile.

The front clip is taken apart as Steve cuts the radiator support loose.

The floors are removed the seat box cut free and everything is taken down

to the smallest part. Items that are going to be reused are headed to our

paint shop for cleaning to get ready for new paint, and other new found

problems are added to our work list.

The radiator support in this 88 is really bad. A lot of people search high

and low for another one to use, but these pieces are becoming rare and

next to impossible to find in rust free condition. There is an easy and

permanent solution though.

A friend of ours named John Gerding makes a lot of really great products

for Series Land Rovers from stainless steel. In the images above you can

see his stainless steel radiator support for the early Series IIA Rovers.

We use these on all our SII and SIIA restorations, they are that good.

We also use John's stainless fuel tanks and other products of his. His

fabrication skills are of artisan quality and his pieces are direct replacements

that are far superior to the factory part. John was gracious enough to

donate this piece to the Rover-Haulin project. We'll get it sent down to

the paint dept. for primer and paint to get it ready to go into the new

QE I.

Now that the easy to remove parts are gone and the front clip has been

removed the attention turns to getting the bulkhead out and evaluated.

Things are not looking good for this bulkhead. In the image above you can

see that we have uncovered numerous layers of fiberglass that were posing

as the RH footwell. This is the reason the heater fell into the interior,

there is no steel structure on this side of the bulkhead at all.

The LH footwell isn't looking much better. There are 3 layers of patches

on this side, and all of them are rusted through. One good kick here and

you could see the interior of the Rover.

Under all that crud is supposed to be a steering box, somewhere. Once we

chiseled all the goop off we found that even with this level of crud around

the it, the steering box had no fluid in it. Needless to say this will

make a Rover drive poorly and likely means a steering box rebuild will

be in order due to bad bearings and races.

Seeing how bad the steering box was on the Rover actually gave us a little

inspiration. Inspiration to add more work to our work list. Yeah, adding

work sounds little nuts with only 6 days to do this entire project, but

it is that ECR attention to detail coming back to haunt us. We took a look

at the VIN (Vehicle I.D. #) on Jeff's Rover and found out that a lot of

the set up on the 88 was wrong. Over the years Rovers get taken apart,

parts get taken off and the wrong stuff goes back on. A previous rebuilder

of this 88 built sort of a mongrel. Later model pieces, like the steering

wheel, are in this early Series IIA. The wheel should be what is know as

a banjo type, not the later type shown above. The hood should be a deluxe

dished one and so on. So now we have decided to not only get this 88 back

in order, but put it back to as original as we can. That means the right

wheel, the right hood, the correct sills and more. At ECR we have always

said it doesn't take any more time to do it right, so we'll be putting

that to the test in the next 5 1/2 days, as day 1 is now half over.

Here you can see that the bulkhead is nearly ready to be removed. Steve

is taking out the last bolts, but the bulkhead isn't making the grade.

Extensive rust in all the wrong places means that there is no way to save

it. Even if we had the time to do the fabrication there are some bulkheads

that even ECR can't save, and this is one of them. So all the parts are

stripped off the bulkhead and it is headed to the scrap pile. Time for

plan B.

A rebuildable SIIA bulkhead was sourced from our inventory and Ian quickly

got to work on making it rust free. The floors where replaced and any and

all rust repairs were completed.

We also made the needed changes to the bulkhead that will allow us to install

the updated power brake system and the updated Mansfield heater set up

from Rovers North. We make all these changes before the bulkhead is primed

so the steel surfaces stay sealed in primer.

Once all the fabrication work on the bulkhead was complete it was handed

over to Mike to media blast back to white metal. It isn't a fun job, but

it is part of making a Rover last a long time. The paints and primers we

use are only as good as the surface they are applied to. If you scrimp

on the preparation, the paint is worthless.

Here you can see the bulkhead has been blasted and it now in our paint

shop for hand sanding and final prep. for at least 3 coats of PPG rust

resistant primer.

After hours of preparation the bulkhead is now in primer and has been put

through a bake cycle in our 1,000,000 BTU bake booth were it is baked at

140 degrees for 45 minutes to cure the primer. The bake booth allows us

to quickly and properly cure the chemicals in the paint and aids in a stronger

chemical bond of the materials and a better final product. If we did not

have the bake cycle in our state of the art spray booth, or if we relied

on an outside paint shop we could never do this project. The bake booth

will allow us to get the bulkhead primed and into the correct Pastel Green

color by the morning of day 2.

As primer and paint coats dry in the spray booth, Mike takes time to prep

the other new parts for the project. Here you can see the new door tops

with new glass and window tracks are being masked off for primer and paint.

Why is Mike getting those new doors and door tops ready for paint? When

we took off the door trim on the RH door of the Rover this is what we found

underneath, basically nothing but a few flakes of rust. The 88 has to have

new doors and door tops on both sides.

So now you have seen a little bit of what you can find "underneath

and behind" an otherwise nice appearing Rover. Hopefully these images

will make you think twice about buying that Series Rover, or any Rover

for that matter, without going over it yourself. We see so many people

screwed on internet purchases that we hope these images will slow down

that trend. We know it won't but we have to try. Everything looks great

on eBay... right?

3/4 of the way through day 1 and the QE I looks a little worse for wear,

but like we always say, "It gets a lot worse before it gets better."

The body has been removed, new panels sourced and sent to paint as required.

The wiring removed and everything taken part.

Even at this stage, with the Rover this far apart, new surprises are always

just around the corner. Here is a really nice way to hang your exhaust

system. Forget the rubber isolators and go for your dog's leash! Seriously,

that really is dog chain holding up the exhaust.

As we continue the Rover offers up stuck bolt after rusted nut in a vain

attempt to try and stay together, but it has no chance. We have all the

tools including cutting torches and plasma cutters, and we have been doing

this for a long time.

The drivetrain is removed in one piece and now we can begin to cut the

axles free from the old rusted chassis to get them ready for the new galvanized

frame and parabolic suspension from Rovers North.

Now that the engine and transmission are on the floor we can go after a

number of broken parts and replace numerous leaking gaskets so that the

88 can start to live down its reputation of the being the biggest oil leaker

we know.

The last step in the tear down is to remove the few last remaining parts

from the old chassis that will be needed on the new one and then get the

old chassis out of the shop and onto the scrap pile. Once that is torn

down we do a quick cleaning of the shop, organize the parts and we'll start

fresh in the morning. It is the end of day 1.

Click the days below to see the progress of that day. These pages have

lots of images.

INTRODUCTION

DAY 2: FRIDAY

DAY 3: MONDAY

DAY 4: TUESDAY

DAY 5: WEDNESDAY

DAY 6: THURSDAY

DELIVERY DAY