Please be aware that ECR is now a Defender repair and modification shop only.

We no longer work on Range Rovers, Discos or Series Rovers.

These pages are from work we did in the past and left up for your enjoyment.

Series IIA 88 Rolling Coil chassis,

bulkhead work, 5 speed conversion and more

This Late Series IIA has been brought to us by a customer in MA. The donor is a complete basket case in need of just about everything, but the good news is that this 88 will be getting a new galvanized coil sprung chassis as well as a 5 speed conversion and a new motor. As with any restoration process the first step is to tear down the donor vehicle. In this case we are not doing the entire project. The customer has contracted us to set up the rolling chassis, restore a bulkhead for him, and drop the driveline in place. The customer wishes to complete the rest of the work.

Once the donor 88 has been taken apart, we can go after the parts that we will be working with. The differentials, the transfer case and the bulkhead. In the image above you can see that we have stripped the bulkhead of all its parts and have installed it in our bulkhead jig. There isn't much good on this one, but we can make it live again.

You can see above that the LH bulkhead foot is completely gone, as is a good part of the door post. The floor areas are bad, as is the center section.

Here you can see the RH side of the bulkhead. It is also missing its foot, a good section of the floor and door post, but the top section is worth saving, so we'll begin by cutting out all the rusted steel so we can start over with good metal. For more information on ECR bulkhead restorations go here!

Once you remove all the rotted and rusted steel you end up with what you see in the image above. From this piece we can build a perfect rust free bulkhead, with new galvanized parts for long life. We'll also be running the bulkhead through our dunk tank system for even better rust protection.

Another system that we will be working with on this rolling chassis is the gearbox and transfer case. This image shows the gearbox assembly as it was removed form the 88. Man what a mess, this thing has obviously been leaking for a few decades and had no maintenance. The good news is that we won't need to worry about the gearbox condition, as this chassis will be getting a new R380 5 speed conversion. We only need to split off the transfer case, clean and rebuild it and then mate it to the new 5 speed.

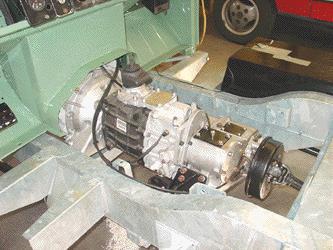

Here you can see the transfer case, removed from the old 4 speed gearbox, cleaned and ready for evaluation. Each part of the transfer case will be double checked, needed pieces will be replaced and then the unit will be assembled and made ready for the new R380 5 speed.

In this image you can see that the bulkhead fabrication is done, and the piece is now going through what we call our "dunk tanks". We have 3 of these custom made tanks that hold a really nasty rust preventative primer. Once a bulkhead is built, we then "dunk" the top section and both the left and right door posts. This gets thick paint inside all the areas that are prone to rust. We do this because no matter what primers or paints we spray on, we'd never get coverage in these internal areas, but the dunk tanks take care of that for us by coating all the parts inside and out.

This close up of the LH door post dunk tank shows that the entire area is saturated with paint giving an ECR bulkhead the maximum rust protection available. In this image you can also see the galvanized panels that we use to repair the bulkheads. These pieces have all the proper stampings and will last a long time.

Here you can see the completed bulkhead ready for paint prep work. Notice that we have already made all the needed modifications to fit the customers desired upgraded heater system, the upgraded brake pedal box and we've also filled in any non-factory holes that got drilled in the bulkhead over the last 30 years. Once painted this piece will last decades and it is correct right from the stamps in the floor, to the lip on the door post for the door seal. This ECR bulkhead has been jig built for a correct fit, the panels are galvanized for long life and it will appear factory fresh once painted and installed. We have a lot of customers that search the world over to find rust free bulkheads for their Series IIAs, and what they end up with is a bulkhead that is usually damaged, poorly patched by a previous repair, doesn't fit the application correctly and still has rust. When it comes to bulkheads, there really is no miracle cure for the Series IIA pieces. You can search for that needle in the haystack (but why would anyone take out an un-rusted bulkhead) or you can have us build you one that is better than the factory unit, correct for your needs (be it Tdi, V8, whatever) and that will last longer. The choice is yours, but we think the right way is the only way. The ECR way. This bulkhead will now move over to our paint dept. for prep., epoxy primer, and a few coats of light green (the customers new color for his project).

In the image above you can see the galvanized coil chassis being assembled and made ready for the drivetrain. The front and rear suspension system are now in place and work continues on the brakes and steering. The donors 88s 4.70 ring and pinions have been checked and rebuilt onto 24 spline axle differential carriers for added strength and installed into the Defender axle tubes as shown above. The new galv. coil chassis will give this 88 4 wheel disc brake, better suspension, easier steering and a host of other upgrades. For more information on Series II/III coil sprung conversion go here.

Here you can see the completed 5 speed gearbox and transfer case, ready to mate to the engine. This set up will give years of trouble free service for the 88 without the need for any overdrives. The full synchro 5 speed R380 offers all your gears on one lever and long term durability.

This image shows the ECR built 5 speed gearbox and Series transfer case set up in the coil chassis, mated to a 2.0 Chevy engine that the customer supplied. With a little extra power, and a reliable and tough 5 speed gearbox as well as a coil chassis with 4 wheel power disc brakes this 88 project should be ready for anything once it is complete.

In this image you can see the 88 galvanized coil chassis set up as a rolling chassis, with the engine and gearbox mounted in place. We've started to run the brake pipes and have installed a new steering relay as well as an OME steering stabilizer so that the 88 will handle great once complete. Also notice that the fuel tank is in place and the new rotors and calipers have been installed.

Across the hallway in ECR's paint department, the rebuilt bulkhead is now ready to be installed on the chassis. The bulkhead has been fully restored back to as close to original as possible, but with better materials and more modern coatings used this time around. The customer wanted his new 88 to be green, so we have fully seam sealed the bulkhead and given it 3 coats of epoxy primer, and then 3 more coats of PPG top coat in the correct Pastel Green. Next we'll install the bulkhead on the chassis and start hooking up systems and then the 88 rolling chassis will be ready for the customer to finish it up.

Here you can see the completed rolling chassis with the bulkhead installed. We have also installed the new power brake system and run the brake lines to the brake calipers on each corner, set up the steering and installed some junk rims and tires so that it can be more easily moved about.

In this image you can see that we have installed the dash panels on the new bulkhead. We also installed a new wiring harness that is already set up for an alternator and made all the needed changes in the wiring to work with the new systems in the 88. The fuel tank, rear wiring harness, etc are all in place, ready for the customer to restore his body panels and then start the assembly of the body and the 10,000 other details needed to complete a restoration.

The image above shows the completed 5 speed conversion in this 88 chassis. The R380 5 speed is mated to the Series IIA transfer case, and as you can see all the systems fit well and look pretty much stock once installed, from speedo cable to reverse light wiring. The driveshafts have been altered to the needed lengths and installed in the rolling chassis, giving this 88 a tough, long lasting 5 speed gearbox that has no need for sometimes troublesome Overdrives.

From the front you can see we have also installed a Mansfield Heater kit to give this 88 not only the benefits of 4 wheel disc brakes and a better ride from the coil chassis, but the ability to actually heat the interior and defrost the windscreen when you need it.

Here you can see the completed bulkhead, just the way the customer asked for it, ready so he can finish up the project.

This image shows the completed rolling coil chassis, ready for delivery. This chassis has a host of upgrades from a new engine, to a R380 5 speed gearbox, a new wiring harness to a galvanized coil suspension system with 4 wheel disc brakes. Once finished this will be a great 88 that will give years and years of trouble free service. If you need a new Series IIA bulkhead, or just an suspension upgrade we can help put your Series Rover at the tops of its game... just like this one.